In industrial fields, composite materials refer to those made by combining two or more materials with different properties through physical or chemical means. This combination results in a new material with new performance characteristics. The basic idea is to combine the advantages of different materials to make up for the shortcomings of single materials. This leads to a new material with better overall performance.

1.Components of Composite Materials

Composite materials usually consist of two parts. These are the matrix material and the reinforcement material.

1.1 Matrix Material

The matrix material acts as the continuous phase. It bonds and supports the reinforcement material and transfers loads. Common types of matrix materials include metals, polymers, and ceramics. Metal matrices include aluminum, magnesium, titanium, and steel. These are used in high-performance structural parts such as aerospace components. Polymer matrices include epoxy resin, polyester, and nylon. This type of matrix is the most widely used. It appears in automobiles, construction, sports equipment, and more. Ceramic matrices include alumina and silicon carbide. These materials resist high temperatures. They are often used in aerospace and energy fields.

1.2 Reinforcement Material

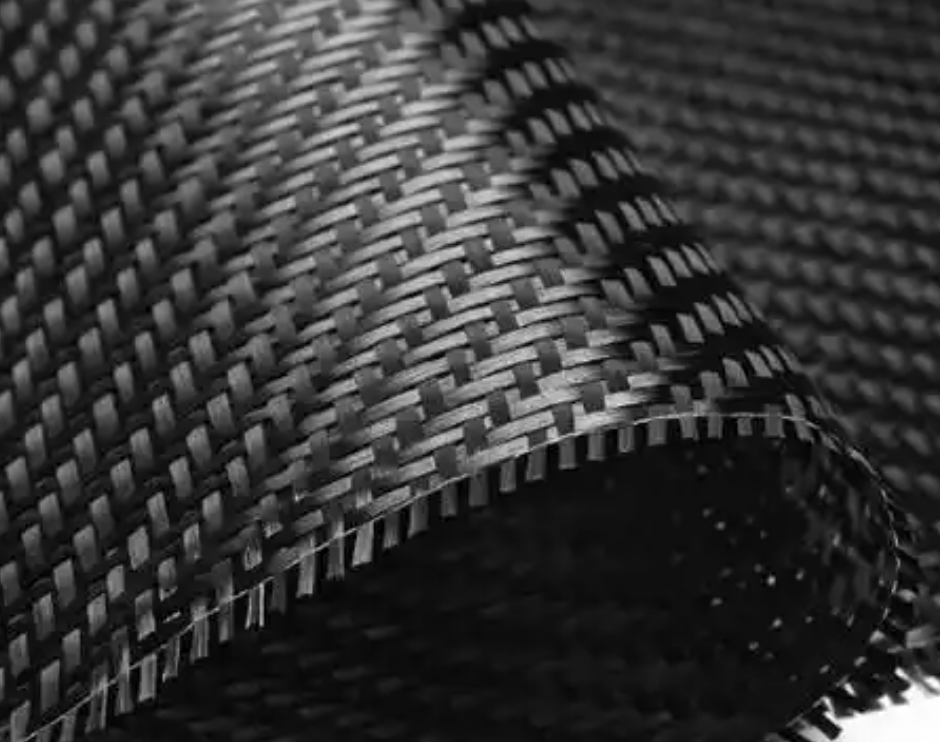

Adding reinforcement materials gives composite materials their strength and stiffness. Common reinforcement types include fibers, particles, and sheets. Fiber types include glass fiber, carbon fiber, aramid fiber (Kevlar), and boron fiber. These mainly improve strength and stiffness. Particle types include silicon carbide particles, alumina particles, and metal powders. These enhance hardness and wear resistance. Sheet types include mica, glass flakes, and metal foils. These mainly enhance directional performance or provide barrier functions.

2.What Are the Characteristics of Composite Materials?

2.1 Customizable Performance

Researchers can adjust the types, ratios, and distribution of matrix and reinforcement materials (often referred to as the formula). This allows them to meet different needs in a custom way. Goals include light weight, high strength, corrosion resistance, and heat resistance. Of course, a single composite material usually only excels in one or two performance metrics. We don’t yet have one that performs well in all aspects. You can select matrix and reinforcement materials based on the properties you want. You can also adjust their ratios and distribution.

For example, if you need a material with high tensile strength that is also very light, you can choose epoxy resin as the matrix. You can then use carbon fiber as the reinforcement. The resulting carbon fiber-reinforced epoxy resin has a tensile strength over five times higher than steel, yet its density is only one-quarter that of steel. This means that this common composite is both lighter and stronger than regular steel. It perfectly matches your goal. You should know that composite materials offer strong design flexibility. For instance, if you need even higher tensile strength, you can switch from T800 carbon fiber fabric to T1000 or even T1100 models to meet your needs.

2.2 Synergistic Effect

Composite materials are not just simple mixtures of matrix and reinforcement materials. Instead, they work through physical bonding to create synergy. This results in combined properties that single materials cannot achieve. This “performance complementarity” means the combined performance is much better than simply adding the two materials’ properties.

Let’s look again at carbon fiber-reinforced epoxy resin composite (CFRP). Epoxy resin, as the matrix, has good adhesion, chemical resistance, and processability. However, it is weak and brittle. On the other hand, carbon fiber has high strength, high stiffness, low weight, and good fatigue and corrosion resistance. But it cannot handle complex loads on its own. When combined, epoxy resin wraps around the carbon fiber and forms a solid whole. It transfers external loads evenly to the carbon fiber and prevents fiber slippage and breakage. Carbon fiber bears most of the stress. Through this synergy, their properties complement each other. Compared to pure epoxy resin, the tensile strength of the composite increases by 10 to 20 times. Its elastic modulus rises by 25 to 75 times. It keeps its lightweight advantage and greatly improves fatigue resistance. This mechanism is similar to reinforced concrete. Carbon fiber acts like steel bars, providing strength. Epoxy resin acts like concrete, holding the structure and transferring forces. It also spreads out defects and stops cracks from growing.

2.3 Multi-functionality

Single materials often have performance limits. Composite materials can overcome these limits through smart combinations. They can have many functions at once, such as conductivity, thermal conductivity, insulation, wave transmission, and shock absorption.

Take carbon fiber-reinforced ceramic matrix composites as an example. Silicon carbide ceramics are heat- and corrosion-resistant. But they are insulators and have poor conductivity and high brittleness. Carbon fiber has good conductivity and thermal conductivity. But it oxidizes easily, cannot handle complex loads, and cannot transmit waves. Alone, neither material meets all the demands.

When carbon fiber and silicon carbide ceramics combine, they form a carbon fiber-reinforced silicon carbide ceramic matrix composite (C/SiC). Its performance improves greatly. Carbon fiber creates a 3D conductive network in the ceramic. The composite’s electrical conductivity increases sharply, nearly reaching that of metal alloys. Its thermal conductivity along the fiber direction also improves greatly. In terms of mechanical performance, the ceramic provides rigidity, while the fiber offers flexibility. Energy is absorbed through a “fiber pull-out effect.” This boosts fracture toughness and shock absorption. Notably, by controlling fiber orientation and distribution, the composite can remain insulating in some directions. It also has good wave transmission at microwave frequencies. This allows it to combine conductivity, thermal conductivity, insulation, and wave transparency in one material.

3. Common Composite Materials in Industry

3.1 Glass Fiber Reinforced Polymer Matrix Composites (GFRP)

Glass fiber reinforced polymer matrix composites use glass fibers as the reinforcement and polymer resins (such as epoxy resin or unsaturated polyester resin) as the matrix. For example, offshore wind turbine blades are made by combining glass fiber cloth with epoxy resin. The glass fibers provide high-strength support, while the resin gives the material overall toughness and moldability. This material stands out for being lightweight and high-strength, with a density only one-fourth that of steel. It also offers excellent corrosion resistance, meeting the signal transmission requirements of wind power equipment.

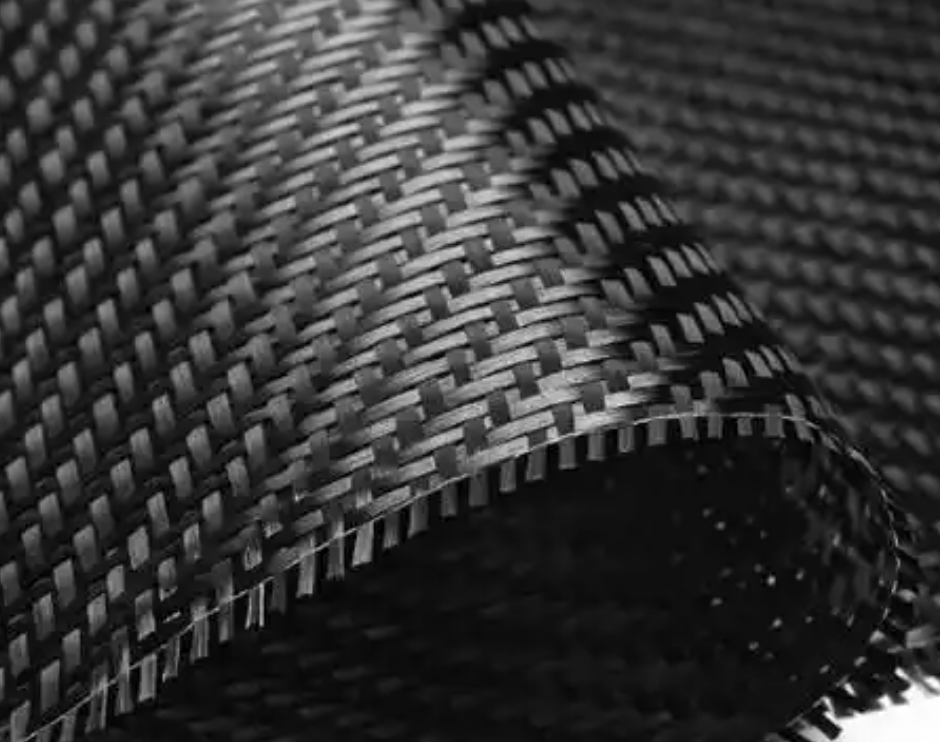

3.2 Carbon Fiber Reinforced Polymer Matrix Composites (CFRP)

Carbon fiber reinforced polymer matrix composites use high-strength carbon fibers as the reinforcement and epoxy resin or other polymer materials as the matrix. In the aerospace industry, aircraft structural components like the Boeing 787 fuselage extensively use CFRP parts. The material consists of high-modulus carbon fibers and high-temperature-resistant epoxy resin. These two components are formed through prepreg layering and hot-press curing. In terms of performance, CFRP has a strength-to-density ratio 5-10 times higher than steel. Its fatigue life exceeds that of metal materials by more than 10 times. It also has an extremely low thermal expansion coefficient, ensuring dimensional stability under extreme temperatures. This helps reduce aircraft weight by 15-20% while improving fuel efficiency.

3.3 Metal Matrix Composites (MMC)

Metal matrix composites use metals as the matrix and incorporate reinforcements like ceramics or carbon fibers. For example, aluminum-silicon carbide composites (SiC/Al) are widely used in electronic heat dissipation. This material combines micron-level silicon carbide particles with aluminum alloy through powder metallurgy. It exhibits high thermal conductivity and a low expansion coefficient. It can quickly dissipate chip heat and prevent solder joint failure caused by thermal expansion. At the same time, it offers lightweight properties and high hardness (three times higher than pure aluminum). These features meet the reliability and miniaturization demands of high-frequency electronic devices.

3.4 Ceramic Matrix Composites (CMC)

Ceramic matrix composites use ceramics as the matrix and incorporate fiber or whisker reinforcements. A typical example is silicon carbide fiber-reinforced silicon carbide matrix composites (C/SiC), used in aircraft engines like turbine guide vanes. The material consists of a silicon carbide fiber weave and a silicon carbide ceramic matrix, with carbon fibers accounting for 40-50%. Its core properties include extreme high-temperature resistance, thermal shock resistance, and vibration resistance. These features significantly improve the lifespan and reliability of turbine vanes under high-temperature gas erosion.

3.5 Hybrid Composites

Hybrid composites combine two or more types of reinforcements in the same matrix. A common example is epoxy resin matrix composites reinforced with both carbon fiber and glass fiber. This material is widely used in civilian drone frames. The composite uses 30% carbon fiber and 70% glass fiber, combined with epoxy resin for curing and molding. Its performance highlights include a 40% lower cost compared to pure carbon fiber structures. At the same time, it maintains high strength, offering a 30% improvement over pure glass fiber composites. It balances impact resistance, lightweight properties, durability, and cost control to meet comprehensive needs.

4. Composite Materials Applications in Bicycle Industry

4.1 Structural Components

Bicycle frames, wheelsets, seatposts, stems, pedals and handlebars are the main structural components of bicycles. We need materials with higher strength, lighter weight and better corrosion resistance to manufacture them.

4.1.1 Carbon Fiber Reinforced Polymer Matrix Composites

This is one of the most widely used composite materials in the bicycle industry. For example, the famous French company Look produces carbon fiber bicycle frames. Carbon fiber offers high strength and high modulus characteristics, with tensile strength reaching over 3000MPa. The resin plays the role of bonding and stress transfer, giving the composite material good integrity and impact resistance. Another significant advantage of this composite material is its light weight. It can reduce the frame weight by 30% or more compared to traditional aluminum alloy frames. At the same time, it provides excellent rigidity that effectively transfers the rider’s power, improving pedaling efficiency. It also absorbs vibrations, offering a comfortable riding experience. Additionally, it offers high design freedom, allowing various shapes to meet different aerodynamic and styling requirements.

4.1.2 Basalt Fiber-Carbon Fiber Synergistic Composites

A Chinese technology company has applied this material to electric bicycle frames. Through precise layup design and prepreg compression molding, they produced frames weighing only 1.6kg. Compared with traditional aluminum alloy frames, this reduces weight by 45% while increasing dynamic stiffness by 22%. This composite combines the advantages of basalt fiber and carbon fiber. At only one-third the price of carbon fiber frames, it offers impact resistance comparable to carbon fiber, providing excellent cost performance. Basalt fiber itself has good corrosion resistance and high temperature resistance, making the frame more durable.

4.1.3 Thermoplastic Carbon Fiber Composites

Companies like Specialized and Trek widely use thermoplastic carbon fiber composites in high-end bicycle frames. This material uses thermoplastic resin as the matrix and carbon fiber reinforcement technology. Silicon Valley-based Arevo Company used this material to create “the world’s first 3D-printed one-piece electric bicycle frame.” The frame consists of continuous carbon fiber and thermoplastic composite. The use of thermoplastic material makes the bicycle stronger, more impact-resistant, and lighter in weight. For example, the Super Terra model weighs only 1.27 kilograms.

4.2 Brake Pads

4.2.1 Non-asbestos Organic Composites

The composition mainly includes synthetic fibers such as glass fiber and DuPont Kevlar fiber, along with non-ferrous metals like brass and copper powder, plus magnesium alloy, titanium alloy and ceramic components. Its performance highlights include high wear resistance (2-6 times that of conventional synthetic fiber pads), outstanding noise control performance, and improved heat conduction capability and thermal stability through added metal and alloy powders, making its performance approach that of metallic brake materials.

4.2.2 Semi-metallic Composites

Composed of resin, copper filings and other organic materials, this composite offers direct and sensitive braking response with shorter break-in periods that enable quick adaptation to new braking systems. Compared to resin pads, it better withstands high temperatures and provides a good balance between braking power and wear resistance in daily riding while reducing performance degradation caused by overheating.

4.2.3 Resin Composites

Typically formed by curing fibers and organic materials with resin, this type is commonly used in Shimano systems. It combines the advantages of organic brake pads with harder non-metallic materials similar to sintered pads, offering benefits including light weight, low cost, prevention of heat buildup, requiring less braking force, and quicker adaptation to rims or discs to reach optimal working condition.

4.2.4 Graphene Composites

This material incorporates graphene in pad backplates and friction material heat-resistant coatings. Its excellent thermal conductivity allows faster heat transfer from the disc-pad interface, maintaining more consistent braking performance. According to AbsoluteBlack tests, it reduces pad and disc temperatures by up to 35%, eliminates brake fade, and extends the service life of both pads and discs.

4.3 Brake Calipers and Levers

The brake lever body uses carbon fiber reinforced nylon (like PA6+30% CF), whose high strength and rigidity prevent deformation during frequent operation and strong grip force to ensure consistent braking feel and stability, while its low density helps reduce overall bicycle weight and improve handling performance, with good wear resistance extending the lever’s service life. The caliper bracket uses carbon fiber reinforced nylon that maintains bracket strength while reducing weight, offering better corrosion resistance than traditional metal brackets (preventing rust/corrosion in humid conditions or after long-term use) to ensure stable brake performance, with design flexibility allowing customized shapes and sizes to meet different brake system requirements from manufacturers and riders.

4.4 Bicycle Saddles

Besides common carbon fiber composites, bicycle seats use many other composite materials. Carbon fiber reinforced polyamide (CF/PA6) offers good processability (allowing creation of complex seat components through automated fiber placement) while balancing strength and toughness to meet structural requirements and adapt to different riding postures and forces. Flax fiber composites use flax fiber as reinforcement with resin matrix, whose natural properties provide excellent vibration damping (e.g., bcomp’s amplitex flax fiber composite reduces bicycle vibration by 19.2% in Itaca’s seatpost applications) while offering greater comfort and environmental sustainability. Some saddles use polymer composites as main material with carbon fiber base shells and arches, where the polymer provides flexibility and wear resistance while the carbon fiber components enhance overall strength and rigidity and reduce weight, making this design suitable for different bicycle types including mountain bikes.

5. Future Development Trends of Bicycle Composite Materials

5.1 Consumer Concerns About Composite Materials

The composite materials used in bicycles all come from mature achievements in the industrial materials science field. Therefore, the development of bicycle composites depends more on the overall progress of industrial composites. However, the bicycle industry focuses specifically on certain aspects.

5.1.1 Low Cost

Bicycle pedals are one of the components most concerned with low-cost composite materials. As a frequently used bicycle part, pedals have huge production demands. Using overly expensive composites would significantly increase production costs, hindering market promotion and popularization. For example, using glass fiber reinforced nylon composites to manufacture pedals can meet basic strength requirements while ensuring riding safety. Since the raw material costs are relatively low and the molding process is simple, it effectively controls costs. This allows bicycle manufacturers to maintain product quality while keeping reasonable prices, enhancing market competitiveness.

5.1.2 Lightweight

Bicycle frames are the components most focused on lightweight composite materials. As the core load-bearing structure of bicycles, frame weight directly affects riding efficiency and comfort. For long-distance riding or competitive racing, lightweight frames make it easier for riders to control the bicycle and reduce physical exertion. Carbon fiber composites have become ideal frame materials due to their extremely high specific strength and specific modulus. For example, carbon fiber road bicycle frames can weigh as little as about 1kg, significantly reducing weight compared to traditional metal frames. This helps riders perform better in competitions and makes daily riding more convenient and comfortable.

5.1.3 Rigidity

Bicycle forks have strict requirements on the rigidity of composite materials. During riding, forks bear ground impact forces and control direction, requiring sufficient rigidity to ensure riding stability and handling. If fork rigidity is insufficient, deformation or shaking may occur during high-speed riding or sharp turns, seriously affecting safety. Carbon fiber reinforced epoxy resin composite forks provide excellent rigidity while maintaining light weight. This allows riders to control direction more precisely during riding, enhancing stability and safety.

5.1.4 Corrosion Resistance

Bicycle chains and brake cables are key components requiring corrosion-resistant composites. Chains frequently contact rainwater, mud, and humid air during riding, while brake cables are exposed to the environment, making them prone to corrosion and rust. Corroded chains and cables not only have reduced lifespan but also affect braking and transmission performance, creating safety hazards. Using corrosion-resistant composites like stainless steel fiber reinforced plastic for chains and cables can effectively resist environmental erosion, extend component lifespan, and ensure normal bicycle operation and riding safety.

5.1.5 Wear Resistance

Bicycle tires particularly value the wear resistance of composite materials. Tires directly contact the ground and constantly rub against the road surface during riding, potentially being scratched by sharp objects like stones. If tires lack wear resistance, they will wear quickly, requiring frequent replacement and increasing costs. They may also suffer blowouts. Rubber and aramid fiber composite tires leverage the excellent wear resistance of aramid fibers to significantly improve durability and reduce wear. This maintains good tire condition even on complex road surfaces, lowering blowout risks and improving riding safety and economy.

5.1.6 Toughness and Shock Absorption

Bicycle seatposts have high requirements for toughness and shock absorption in composites. During riding, especially on bumpy roads, seatposts need to absorb ground vibrations to provide a comfortable riding experience. If toughness and shock absorption are poor, riders will clearly feel road bumps, causing fatigue during long rides. Glass fiber and elastomer composite seatposts utilize the strength of glass fibers and the flexibility of elastomers to effectively absorb vibrations. They can deform appropriately under force without breaking easily, providing comfortable and safe riding.

5.2 SUMLON’s Additional Expectations

Beyond consumer concerns like lower cost, lighter weight, higher strength, better corrosion resistance, and improved shock absorption, SUMLON believes the bicycle industry can expect more from composite materials. With technological development and growing environmental awareness, composite applications in bicycles are moving toward more diverse and innovative directions.

Regarding environmental performance, the industry can anticipate using biodegradable and recyclable composites. Traditional composites are difficult to dispose of after disposal, easily causing environmental pollution. New biodegradable composites can decompose naturally or through specific treatments after their lifespan ends, reducing resource waste and environmental pressure. Meanwhile, recyclable composites can lower raw material consumption, aligning with sustainable development concepts and supporting the bicycle industry’s green transformation.

Intelligence is another important future direction. Combining sensor materials with traditional composites can give bicycles smart monitoring capabilities. For example, embedding strain sensors in frames can monitor stress conditions in real-time and alert users to potential risks when abnormalities occur, ensuring riding safety. Alternatively, using conductive composites could enable self-powering bicycles to provide energy for lights, smart computers, and other devices, enhancing convenience and technological sophistication.

Furthermore, optimizing thermal properties shows great potential. In high-temperature environments, bicycle component performance may suffer from material deformation. Developing composites with excellent thermal stability would ensure normal operation under extreme temperatures. In cold environments, thermally insulating composites could improve riding comfort, expanding bicycle usage scenarios.

As technology continues to advance, these expectations for composite material performance will gradually become reality. Such improvements will not only provide consumers with better riding experiences but also drive the bicycle industry toward higher development levels.

By the way, SUMLON has been manufacturing bicycle parts for over 15 years. Contact us if you are looking for a bike parts factory or a one-stop wholesaler. Peace.